Welcome to our comprehensive guide on how to ensure the highest quality of grounded bones when using your very own chicken bone grinder. Whether you’re a pet owner looking to make homemade pet food, a chef seeking to enrich your recipes with the goodness of bone meal, or simply someone who prefers to waste no part of the animal, this step-by-step tutorial will equip you with the knowledge to yield exceptionally high-quality, nutrient-rich grounded bones with ease and efficiency.

While operating a chicken bone grinder may seem straightforward, there are crucial steps and precautions that cannot be overlooked if you want to guarantee the best results. In this guide, we will delve into the techniques that will help you achieve the finest consistency, maximum nutritional value, and most importantly, ensure your safety throughout the grinding process. From selecting the appropriate bones to cleaning and maintaining your grinder, we will cover every aspect that will help you produce top-notch grounded bones that you can confidently incorporate into your desired applications. Let’s get started!

How to Choose the Best Chicken Bone Grinder

Assuming you’re in the market for a chicken bone grinder, there are several important factors you should consider to ensure you choose the best one for your needs. By taking these factors into account, you can make an informed decision and invest in a grinder that will deliver high-quality grounded bones every time.

Factors to Consider when Buying a Chicken Bone Grinder

When choosing a chicken bone grinder, there are a few key factors you should keep in mind:

- Motor Power: The motor power of the grinder is crucial in determining its efficiency. Look for a grinder with a powerful motor that can handle the demand of grinding chicken bones effortlessly.

- Durability: Since grinding bones can be a tough task, it’s essential to invest in a grinder that is made of sturdy materials and built to last. Stainless steel and heavy-duty plastic are commonly used materials for bone grinders.

- Grinding Capacity: Consider the amount of bones you need to grind at a time. Depending on your needs, choose a grinder with an appropriate grinding capacity. Opting for a grinder with a larger capacity can save you time and effort in the long run.

- Safety Features: Grinding chicken bones can pose certain risks if not done properly. Look for grinders that come with safety features such as overload protection, secure locking mechanisms, and a built-in cooling system to prevent overheating.

Knowing these factors will enable you to select a chicken bone grinder that suits your requirements and guarantees optimal performance.

Top-Notch Brands of Chicken Bone Grinders

While there are several reliable brands available in the market, these two stand out as the top choices for chicken bone grinders:

1. BoneMaster: Known for their superior quality and durability, BoneMaster grinders are designed specifically for grinding bones. With powerful motors and heavy-duty construction, these grinders offer exceptional performance and longevity.

2. GrindPro: GrindPro is another reputable brand that specializes in bone grinding equipment. Their grinders are engineered to handle the toughest bones with ease, thanks to their robust motors and advanced grinding mechanisms.

When investing in a chicken bone grinder, it’s crucial to opt for a reputable brand that prioritizes safety and reliability. Both BoneMaster and GrindPro have established themselves as leaders in the field, ensuring that you get a grinder that delivers exceptional results consistently.

How to Set up Your Chicken Bone Grinder

One of the essential steps in ensuring quality grounded bones from your chicken bone grinder is setting it up correctly. A properly assembled grinder will not only enhance its performance but also prolong its lifespan. In this chapter, we will guide you through the step-by-step process of assembling your grinder, as well as provide troubleshooting tips for common set-up issues. Let’s get started!

Step-by-step Guide on Assembling Your Grinder

When it comes to assembling your chicken bone grinder, following a systematic approach will ensure a successful set-up. Here’s a breakdown of the process:

| Step | Description |

|---|---|

| Step 1: | Unbox all the components and lay them out in a well-lit and clean workspace. Ensure you have all the necessary parts. |

| Step 2: | Refer to the instruction manual provided by the manufacturer. Familiarize yourself with the different components of the grinder. |

| Step 3: | Attach the grinding plate to the grinder head, ensuring a tight fit. Consult the manual for the recommended plate size for your desired bone grinding consistency. |

| Step 4: | Secure the grinder head onto the top of the grinder body, taking care to align the parts correctly. Tighten any fastening mechanisms as directed. |

| Step 5: | Attach the handle or electric motor to the designated port on the grinder body, depending on the type of grinder you have. Ensure a secure connection. |

| Step 6: | Inspect the grinder for any loose screws or parts. Tighten them accordingly to avoid any potential accidents during operation. |

| Step 7: | Before operation, run a test with no bones to ensure smooth and noise-free grinding. Make any necessary adjustments based on your observations. |

Trouble-shooting Tips for Common Grinder Set-Up Issues

Even with careful assembly, you may encounter some common set-up issues with your chicken bone grinder. Here are a few tips to troubleshoot these problems:

- Problem: Your grinder is vibrating excessively.

- Problem: Your grinder is struggling to grind the bones efficiently.

This issue is usually caused by improper alignment of the grinder head. Make sure the parts are securely fastened and aligned correctly. If the problem persists, check for any damaged or worn-out components that may need replacement.

Inadequate grinding performance can result from using a plate with the wrong hole size or a dull blade. Refer to the manufacturer’s recommendations for the appropriate plate size for your desired bone consistency. For dull blades, consider sharpening or replacing them.

Any issues with your chicken bone grinder’s set-up can significantly affect its performance and the quality of the grounded bones. By following these assembly instructions and troubleshooting tips, you can ensure a smooth and efficient operation, allowing you to extract the most out of your grinder while producing high-quality grounded bones.

Understanding the Bone Grinding Process

Despite its seemingly straightforward nature, the bone grinding process is a crucial step in ensuring quality grounded bones from your chicken bone grinder. Understanding the ins and outs of this process will not only help you achieve optimal results but also safeguard against potential challenges that may arise along the way. In this chapter, we delve into the science behind bone grinding and discuss common challenges you may encounter, along with effective methods to overcome them.

The Science of Chicken Bone Grinding

When it comes to grinding chicken bones, it’s essential to remember that bones are denser and stronger than meat. Therefore, the grinding process requires sufficient power and precision to break them down effectively. As you feed the bones into the grinder, the sharp blades rotate at high speeds, effectively pulverizing the bones into smaller, more manageable pieces.

The bone grinder’s power, often measured in horsepower (HP), is a critical factor to consider. The higher the horsepower, the more forceful the grinding action will be, ensuring efficient and thorough grinding. Additionally, many grinders now come equipped with advanced safety features, such as automatic shut-off mechanisms when excess resistance is detected, ensuring your safety during operation.

Common Challenges and How to Overcome Them

One common challenge during the bone grinding process is encountering large or hard bones that can strain the grinder and potentially damage its blades. To overcome this, it’s crucial to be diligent when deboning the chicken, ensuring that only smaller and more manageable bones are fed into the grinder. By taking this precaution, you not only safeguard the integrity of your equipment but also optimize the efficiency of the grinding process.

Another challenge you may face is the accumulation of bone dust and fragments that can clog the grinder’s blades over time. This can hinder the grinder’s performance and may result in unevenly ground bones. Regular maintenance and cleaning of the grinder, particularly removing any bone debris, will help you overcome this issue. Remember to consult the manufacturer’s guidelines on proper cleaning and maintenance methods to ensure longevity and optimal performance of your grinder.

By understanding the scientific principles behind bone grinding and being aware of common challenges, you are well-equipped to ensure the quality of your grounded chicken bones. Taking appropriate measures to address these challenges will not only enhance the durability and effectiveness of your bone grinder but also guarantee the production of high-quality results, ultimately benefiting various applications such as poultry feed, composting, or even homemade bone meal to enrich your garden soil.

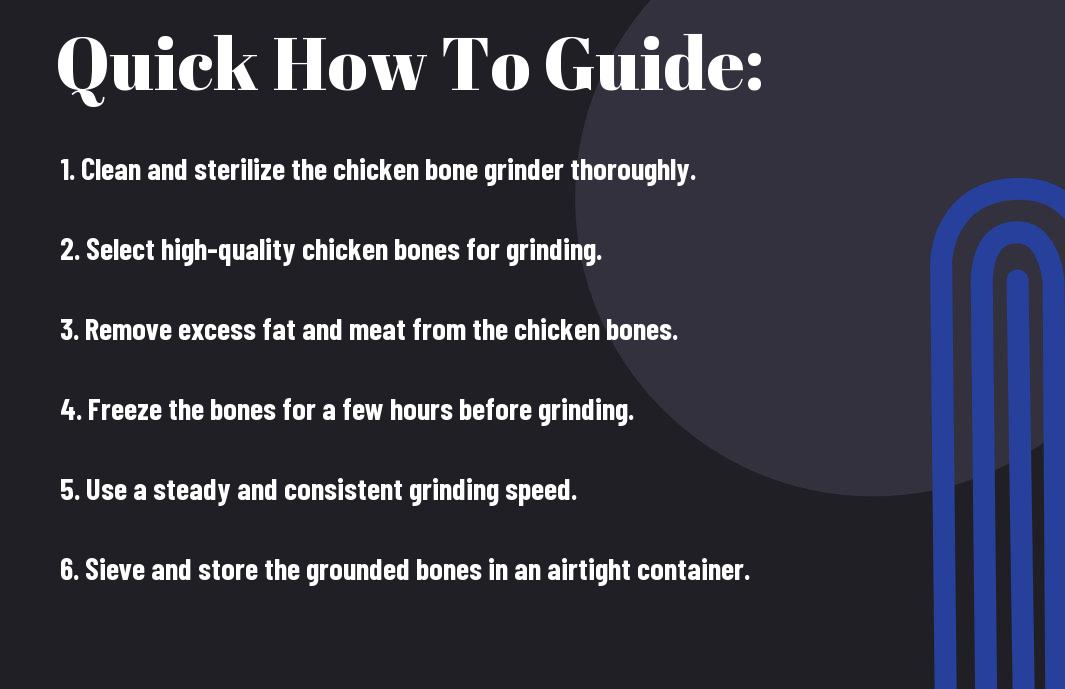

Tips to Ensure Quality Grounded Bones

After acquiring a reliable chicken bone grinder, it’s essential to understand how to achieve the highest quality grounded bones. This chapter will provide you with valuable tips and insights to enhance your bone grinding process and ensure excellent results. By following these guidelines, you will optimize your machine settings, avoid common mistakes, and achieve the best possible outcomes for your grounded bones.

Optimal Grinder Settings for Quality Bones

To guarantee the production of high-quality grounded bones, it is crucial to set your grinder properly. Here are a few guidelines to help you achieve optimal settings:

- Grind Time: Adjust the grinding time based on the desired consistency of your grounded bones. Longer grinding times will result in finer output.

- Speed: It is recommended to set your grinder at a moderate speed to prevent overheating and maintain the quality of the bones. Avoid excessively high speeds that may compromise the integrity of the final product.

- Feed Rate: Pay attention to the rate at which you feed bones into the grinder. Too fast can overload the machine, while too slow may not provide consistent and efficient grinding. Find the right balance for optimal results.

- Temperature: Regularly monitor the temperature of the grinder. Excessive heat can negatively impact the quality of the grounded bones. Take breaks if needed to prevent overheating and maintain optimal temperatures.

By adjusting your grinder settings appropriately, you ensure that the bones are effectively ground without compromising their quality. Pay attention to these factors to achieve the desired consistency and maximize the nutritional value of your end product.

Dos and Don’ts of Chicken Bone Grinding

Ensuring quality grounded bones also involves adhering to some essential dos and don’ts. Here are some valuable guidelines to keep in mind:

Do:

- Do choose fresh, high-quality chicken bones as the starting material for grinding. This will significantly impact the final quality of the grounded bones.

- Do clean your grinder thoroughly before and after each use. This helps prevent cross-contamination and ensures the highest standards of hygiene.

- Do remove any excess meat or tissue from the bones before grinding. This will enhance the grinding process and maintain the quality of the end product.

- Do wear appropriate safety gear, such as gloves and protective eyewear, to ensure your safety during the grinding process.

Don’t:

- Don’t grind bones that are too large or dense for your grinder. This can lead to machine damage and produce subpar results.

- Don’t overload your grinder with too many bones at once. It’s essential to maintain optimal feeding rates to achieve consistent and efficient grinding.

- Don’t grind bones that have been cooked or contain seasoning. This can affect the quality and taste of your grounded bones.

- Don’t forget to follow the manufacturer’s instructions and recommended maintenance procedures for your specific grinder model.

By adhering to these dos and don’ts, you ensure the safety, efficiency, and quality of your bone grinding process. Perceiving these guidelines will allow you to obtain the best possible results, producing grounded bones that meet your desired specifications.

How to Properly Maintain your Chicken Bone Grinder

Last year, you researched and invested in a high-quality chicken bone grinder to effortlessly process bones for your pets or livestock feed. Now that you have mastered the art of grinding bones, it is essential to learn how to properly maintain your grinder. Regular maintenance and cleaning will ensure the longevity and optimal performance of your equipment. In this chapter, we will cover the necessary steps to keep your chicken bone grinder in excellent condition.

Grinder Cleaning and Maintenance Tips

Proper cleaning and maintenance of your chicken bone grinder is crucial to maintain its efficiency and prevent any potential issues. Here are some valuable tips to help you with grinder care:

- Regular Cleaning: After each use, it’s important to thoroughly clean your grinder. Disassemble the various components and wash them with warm soapy water. Pay extra attention to any residual bone particles or grease to ensure a hygienic cleaning.

- Inspect and Lubricate: Periodically, inspect all moving parts, such as the blades, plates, and auger, for any signs of wear and tear. If necessary, replace worn-out parts and lubricate the grinder as recommended by the manufacturer.

- Prevent Clogs: To prevent clogs in your grinder, it is advisable to cut the bones into smaller pieces before grinding. Additionally, avoid excessive feeding, as it can overwhelm the grinder and decrease its efficiency.

- Store Properly: When your grinder is not in use, store it in a clean and dry place. Protect it from excessive moisture or harsh temperatures, as these can cause damage and affect its performance.

Thoroughly following these maintenance tips will help you maintain a clean and well-functioning chicken bone grinder for years to come. Remember, a well-maintained grinder not only ensures the production of quality grounded bones but also guarantees the safety of the equipment and the final product.

Spotting and Addressing Grinder Wear and Tear

Regular inspection of your chicken bone grinder is essential to identify any signs of wear and tear. By promptly addressing these issues, you can prevent any further damage and potential hazards. Here are some important steps:

Visual Inspection: Every few weeks, take the time to inspect your grinder for any visible signs of damage or wear. Look closely at the blades, plates, and housing for cracks, chips, or excessive wearing. If you notice any issues, discontinue use immediately and contact the manufacturer or a professional technician for assistance.

Unusual Noises or Vibrations: While using your grinder, pay attention to any unusual noises or vibrations. Excessive or unusual sounds can indicate a problem with the internal mechanisms. If you experience this, stop using the grinder and seek professional help to prevent further damage.

With regular inspection and prompt action, you can ensure the longevity and safe operation of your chicken bone grinder. Remember, prioritizing maintenance and addressing wear and tear is essential to maximize the lifespan and performance of your equipment.

Making the Most of Your Grounded Bones

However, the process doesn’t stop once your chicken bones are grounded. To truly make the most of your grounded bones, there are a few things you should consider. Whether you plan to use them for cooking, gardening, or other creative purposes, proper handling and storage will ensure their quality and efficacy.

Creative Uses of Quality Grounded Chicken Bones

When it comes to finding creative uses for quality grounded chicken bones, the possibilities are virtually endless. The rich nutrients and minerals present in these bones make them a valuable resource in various areas of your life. Here are a few ideas to inspire you:

1. Soil Enhancer: Grounded chicken bones can be mixed with soil to enhance its fertility. The calcium, phosphorus, and other essential minerals present in the bones act as natural fertilizers, promoting healthier plant growth. Incorporating these grounded bones into your garden or potted plants can provide the necessary nutrients for vibrant and robust plants.

2. Animal Feed: If you have pets or raise animals, grounded chicken bones can be an excellent addition to their diet. Packed with essential nutrients, including calcium and collagen, these bones can help improve bone health and promote healthy joints and teeth in your furry companions. However, before adding them to your pet’s diet, consult with your veterinarian to ensure it’s suitable for their specific needs.

Storing Tips to Preserve the Quality of Grounded Bones

Proper storage is crucial to maintain the quality and freshness of grounded chicken bones. Follow these tips to ensure they retain their nutritional value and effectiveness:

- Store in airtight containers: To protect your grounded bones from moisture and contamination, transfer them into airtight containers. This helps prevent any degradation or loss of nutrients over time.

- Avoid exposure to light and heat: Store your grounded bones in a cool, dark place to minimize exposure to light and heat. These elements can accelerate the breakdown of nutrients and reduce their efficacy.

- Label and date: Label the containers with the date of grinding. This allows you to track the freshness of the grounded bones and ensure you use the oldest batch first.

Perceiving the value of well-preserved grounded bones, it’s essential to handle and store them appropriately. By following these tips, you can prolong the shelf life of your grounded bones and ensure you always have a high-quality resource at hand.

Conclusion

Ultimately, ensuring quality grounded bones from your chicken bone grinder is crucial for maintaining the health and safety of your poultry and ensuring success in various culinary endeavors. By following the guidelines outlined in this guide, you are equipped with the knowledge and understanding needed to achieve optimal results. Remember to select high-quality bones, clean and sanitize your grinder regularly, and use the appropriate settings and techniques to obtain finely-ground bones that meet your specific needs.

By prioritizing quality and taking the necessary steps to ensure the effectiveness and safety of your chicken bone grinder, you can confidently incorporate grounded bones into your recipes, whether it’s for pet food, gardening, or crafting homemade stock. Remember to always prioritize hygiene and follow any additional instructions provided by the manufacturer or recipe guidelines. With a well-maintained grinder and attention to detail, you can consistently produce high-quality grounded bones that will enhance the taste and nutritional value of your meals.